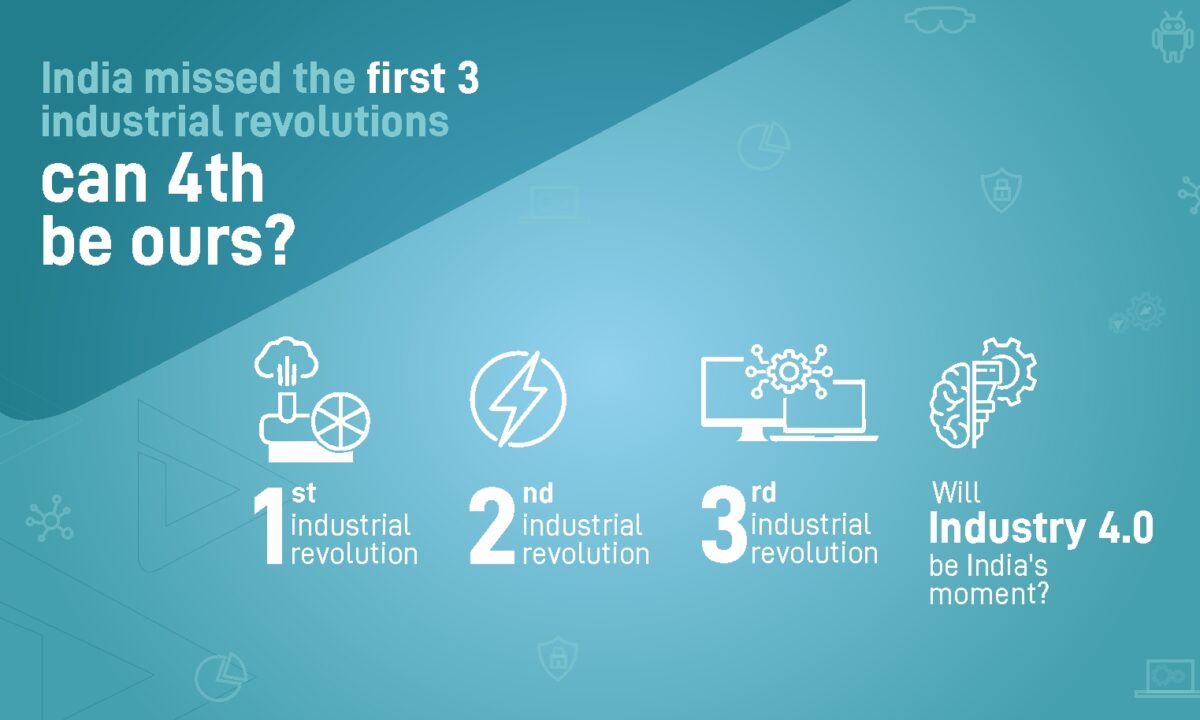

India missed the first 3 Industrial Revolutions – Can Industry 4.0 be ours?

Why India missed the first 3 industrial revolutions?

Picture this: It’s the 18th century, and the world is buzzing with the birth of the first industrial revolution. Steam engines, mechanized textiles, and iron production are changing the face of Europe. India, rich in resources and culture, remains largely untouched by these advancements. Fast forward to the late 19th and early 20th centuries, the second industrial revolution introduces electricity, mass production, and the birth of the modern factory. Yet again, India, under colonial rule, misses the bus.

By the mid-20th century, the third industrial revolution kicks in with the rise of computers, automation, and information technology. India, now independent, begins to catch up but remains largely on the sidelines, watching countries like the United States, Japan, and Germany surge ahead.

And now the fourth industrial revolution is underway!

Industry 4.0: What’s Different?

Industry 4.0 is characterized by a advance of multiple technologies, blurring the lines between the physical, digital, and biological spheres. Key areas include:

Artificial Intelligence (AI)

Internet of Things (IoT)

Robotics

Automation in manufacturing

Smart factory

AR/VR

The question looms large: Can Industry 4.0 be India’s moment?

India is Digital first!

Signs are promising. India has shown incredible growth in the digital space. With widespread smartphone and internet adoption, a digital transformation is underway. Programs like Digital India has made technology accessible to all. Manufacturing industries need to adopt the digital first mindset faster.

The Manufacturing Shift

To truly capitalize on the Industry 4.0, Indian factories must become smarter through the adoption of digitization and automation.

In the first three industrial revolutions, India lacked both the technology and the skill set needed to compete globally. For the first time, India now possesses the requisite technology, skillset and market demand. This combination positions India to lead the way in Industry 4.0.

At Sigma Toolings, we are leading from the front in Smart manufacturing. Our smart factory integrates not just advanced manufacturing techniques but people who have a strong mindset for digital first and automation. We have invested continuously in training, up skilling our workforce to transform from a traditional manufacturing into a Smart Factory.

Our Smart Factory software allows us to monitor and control every aspect of the manufacturing process in real-time, enabling on-time delivery, a fully digital customer experience, with complete transparency. By leveraging advanced analytics and machine learning algorithms, our smart factory software can identify patterns and insights that drive efficiency and productivity.

A shift in mindset is essential for success in Industry 4.0 era. It’s not just about having the latest technology but also about being open to whole new ways of thinking and working. Embracing change and being willing to innovate will make all the difference.

We’re excited about the future and believe that with the right mindset and tools, we can lead the way in Industry 4.0.

Smart Factory is the first step for success in Industry 4.0. At Sigma, we are happy to share our experience and help you to start the journey!