Tooled Up Machines for OEMs

Why Sigma

- Machines delivered production-ready, not “ready to install”

- One accountable team for tooling, fixtures, programming, and validation

- Safe-reach and collision checks before commissioning

- Capability-first commissioning with Cp/Cpk targets agreed then met

- Full handover pack: programs, setting sheets, acceptance criteria, spares

- Proven integration approach for complex precision components

- Faster ramp-up at OEM/supplier site with fewer launch issues

- Transparent documentation that makes audits and PPAP smoother

Where Sigma Fits In

New Line or New Machine for a Critical Component?

Supplier/OEM Needs Standardised, Repeatable Output Across Sites?

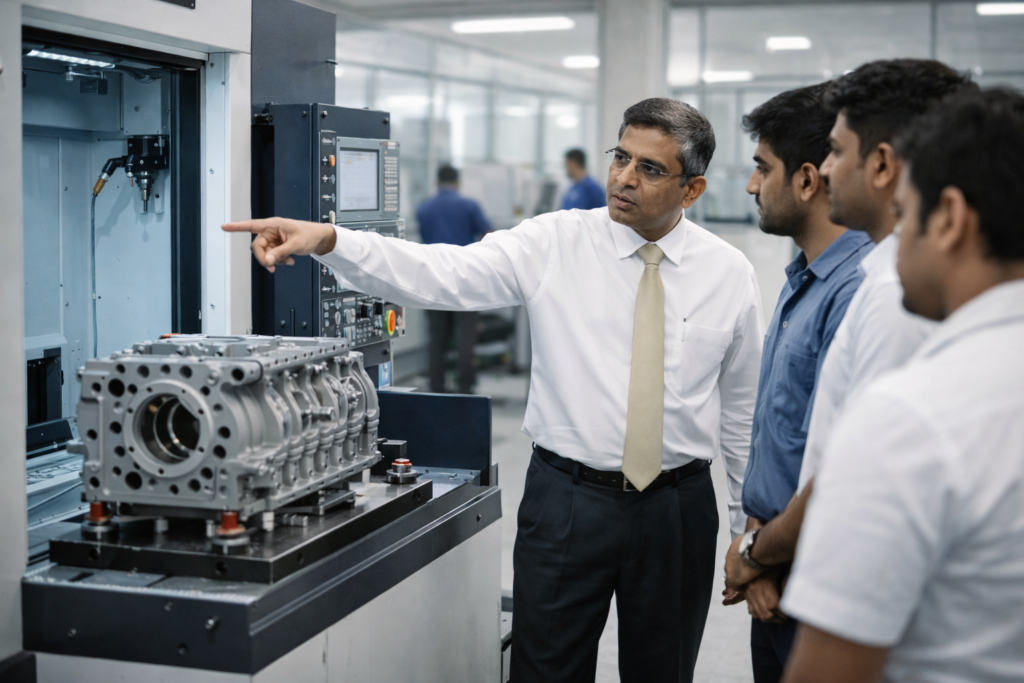

Deliver Machines That Produce from Day One

Capability & Takt Architecture

Scope: Process flow, machine split, rough/finish windows, acceptance criteria.

Deliverables: process architecture, cycle-time study, buyoff checklist.

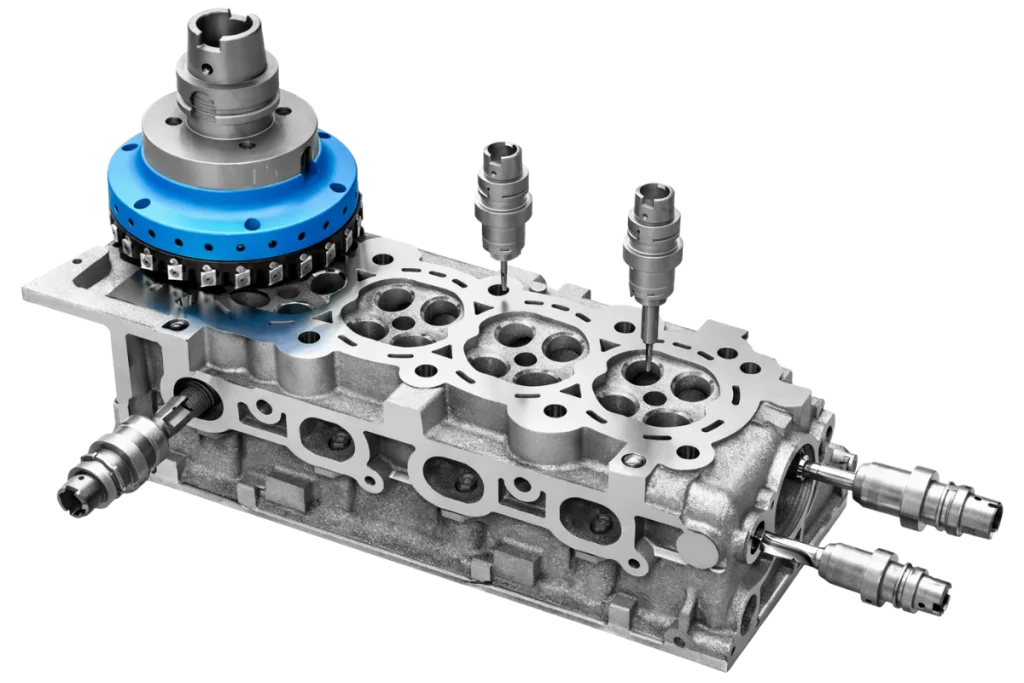

Integrated Tooling & Fixture Package

Scope: Cutting tools + combination concepts + μ-true fixturing as one system.

Deliverables: tool/fixture drawings, BOM, setting/assembly documentation.

Safe-Reach & Collision Validation

Scope: Clearances, reach, stability before commissioning.

Deliverables: 3D collision study, restriction map, envelope harmonisation notes.

NC Program & Parameter Lock

Scope: OEM-specific NC structure, special cycles, stable parameter windows.

Deliverables: NC programs, parameter windows, program documentation.

Commissioning & Capability Proof

Scope: Geometry check, break-in, run-off, Cp/Cpk and PPAP readiness.

Deliverables: geometry check log, capability study, PPAP pack inputs.

Operator/Setter Handover & Sustainment

Scope: Training, troubleshooting playbook, spares/min-max, governance cadence.

Deliverables: handover kit, training notes, spares plan, stabilisation KPIs.

Want us to get back to you?

Recent Blogs

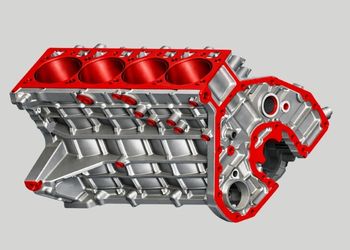

4 Cylinder Block

4 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

3 Cylinder Block

3 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

Tlb Transmission

Tlb Transmission Set-up OP-10 Operation Details : Milling, Drilling, Holemill,