Tool Crib Management

Why Sigma

- Tool crib designed around takt and availability, not admin workload

- Standardisation across parts reduces SKUs and purchasing noise

- Min–max logic based on real consumption, not guesswork

- Tool-life and regrind loop built into daily discipline

- Prevents stock-outs and wrong-tool-at-machine errors

- Visibility into abnormal consumption and cost creep

- Kitting + presetting to cut changeover time

- Simple dashboards that production and maintenance can run

Where Sigma Fits In

Line Stops Because Tools Aren’t Available?

Tool Inventory is High but Still Unreliable?

Make Tool Availability a System, Not a Chase

Tool Master & Standardisation

Scope: Common tools across machines/parts, reduce duplicates, simplify SKUs.

Deliverables: tool master list, standardisation map, approved equivalents.

Min–Max & Reorder Logic

Scope: Consumption-driven stocking, lead-time alignment, criticality tiers.

Deliverables: min–max plan, reorder triggers, critical spares list.

Kitting & Presetting System

Scope: Machine-wise/part-family tool kits, setting discipline, faster changeovers.

Deliverables: kitting plan, setting sheets, crib layout inputs.

Tool Life Tracking & Abnormal Consumption Control

Scope: Track tool life, breakage patterns, regrind cycles, variance causes.

Deliverables: tracking format, abnormal consumption rules, weekly dashboard.

Regrind/Sharpen Loop Management

Scope: Regrind frequency, quality checks, scrap criteria, turnaround control.

Deliverables: regrind SOP, acceptance checks, vendor/turnaround plan.

Governance & Reporting Cadence

Scope: Simple reviews that keep it working without heavy admin.

Deliverables: KPI snapshot template, review cadence, responsibility matrix.

Want us to get back to you?

Recent Blogs

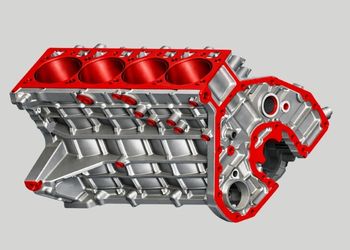

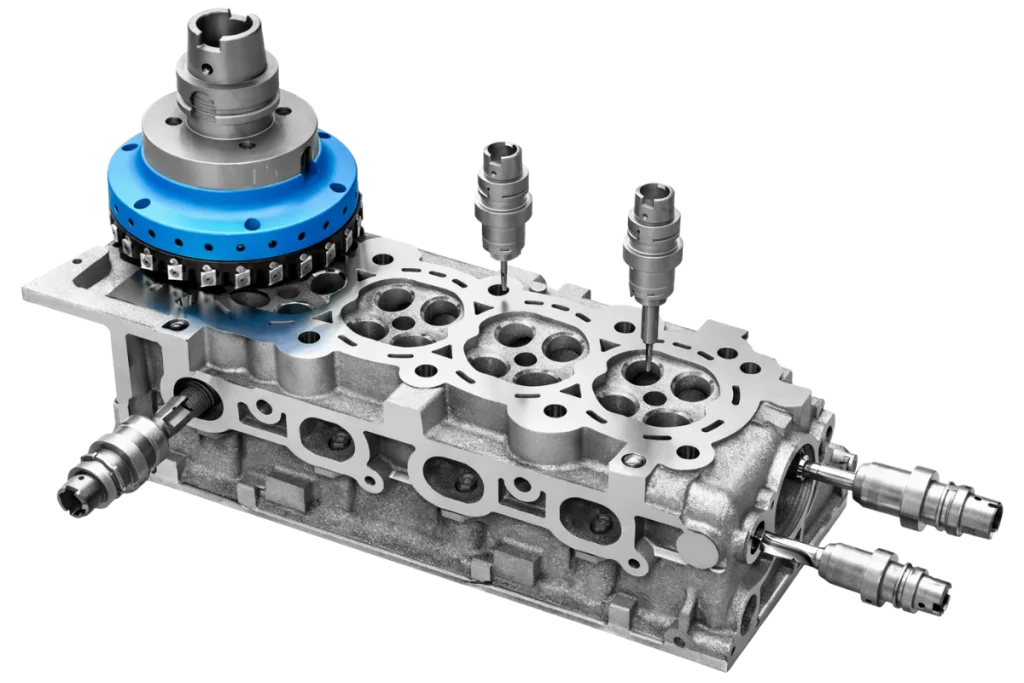

4 Cylinder Block

4 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

3 Cylinder Block

3 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

Tlb Transmission

Tlb Transmission Set-up OP-10 Operation Details : Milling, Drilling, Holemill,