Sigma Inserts

Sigma’s Range of Inserts

Metal cutting and finishing jobs in manufacturing need the right tools for flawless execution. Sigma Toolings offers a wide-range of standard tooling’s to perform these tasks to perfection. Our range of standard tooling’s includes boring bars, inserts, cutters, cartridges, and tool holders.

Our Standard tooling’s are:

- Tested & Certified

- Corrosion Resistant

- Robust

- Durable

- Accurate

Sigma / ISO Insert

Sub Micron Grain Size, Chip Splitting Groove, Plunging Geometry,

‘G’ Class Inserts

Sub micron grain size provides highest rigidity and stability for plunging operation. Chip splitting groove and plunging geometry further reduces chip swarf load which is very important in axial plunging.

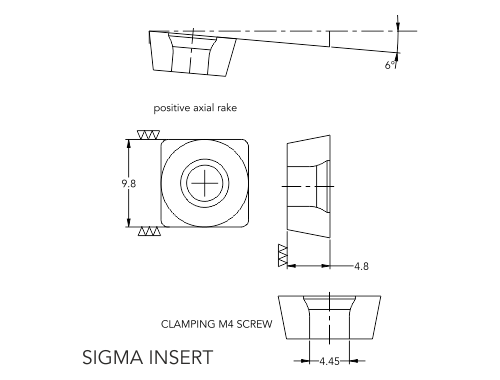

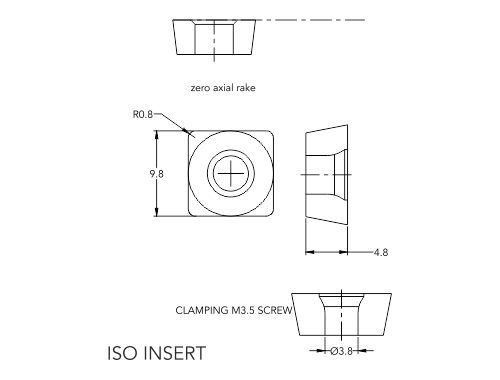

Smallest variation between cutting edges on multi cutting edge tools results in significant performance loss, which is very high with iso inserts. Sigma inserts are flat/bottom, side ground and with precise pockets. Variation between cutting edges will not be more than 0.013 mm radially which substantially increases tool life

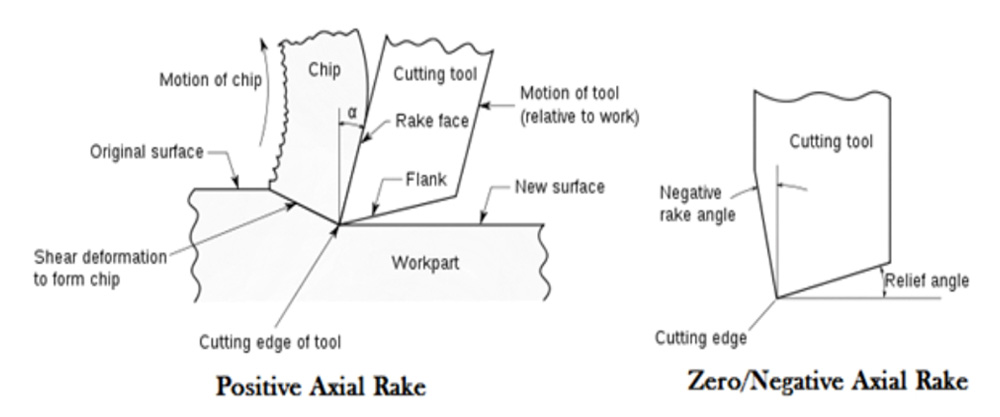

Advantages of Positive Axial Rake

Positive axial rake of sigma tool body and insert lifts the chips away from cutting zone providing easy cutting, less spindle power, while zero or negative axial rake pushes the chips instead of lifting thereby requires more power, more heat at cutting zone due to chip clogging reduces insert life. Positive axial rake reduces spindle load by 30-40% thereby increasing penetration rate and more components per shift.