Engineering Services

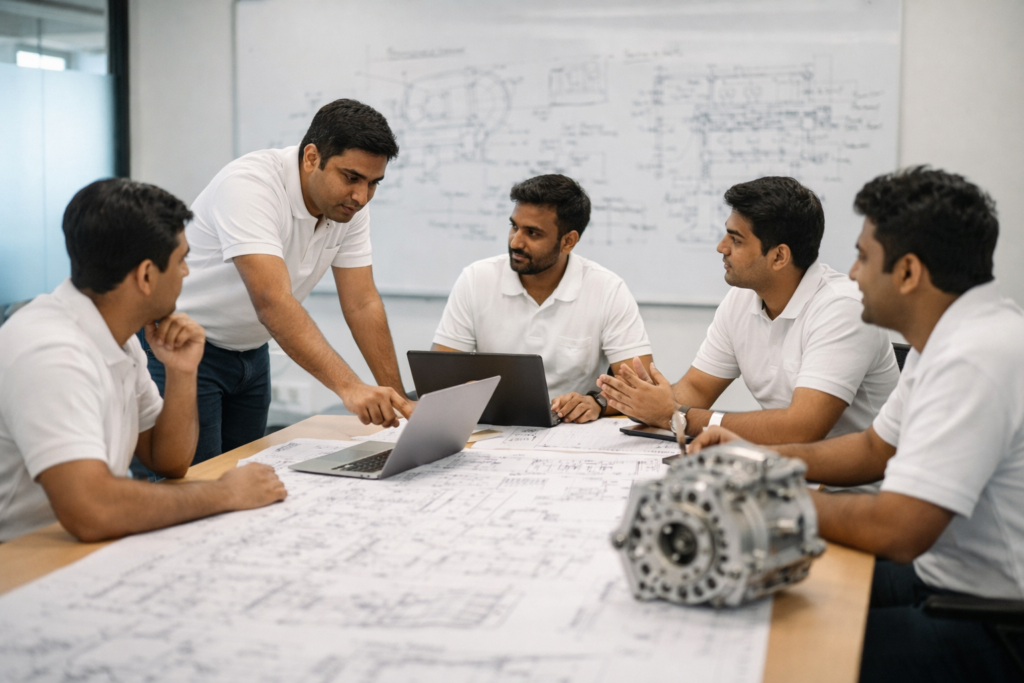

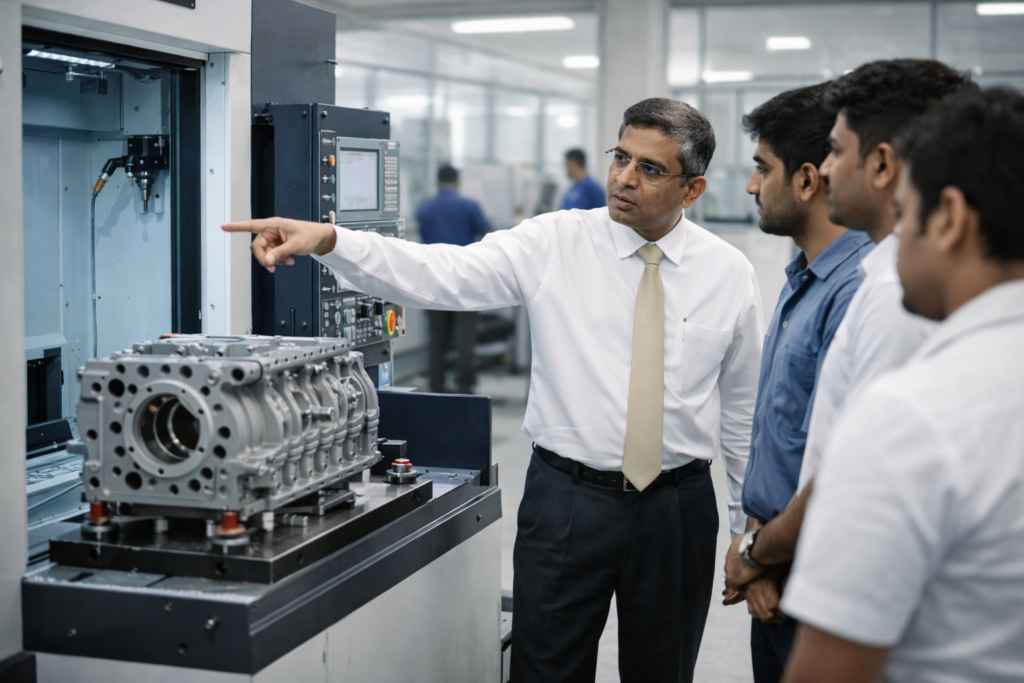

Build Your Competitive Edge with Sigma's Engineering Services

Sigma Toolings partners with you from building the first prototype to stable serial. We work work as a partner owning the journey from process concept to stable production. By closely working with your team our specialists deliver practical innovation, and outcomes you can measure.

Why Sigma

- Full workpiece ownership from experts who’ve launched and stabilized complex engine, transmission or a wide range of precision components.

- Complete process design + implementation from one accountable team.

- Latest machining strategies proven on shop floors.

- Efficient, cost-optimized tooling that protects CPC/CPP at every scale.

- Creating a seamless manufacturing process managing everything from tool, workpiece, appropriate fixture, machining strategy, coolant optimisation, to alignment with gauging.

- Quality & reliability from day one: Cp/Cpk targets agreed, then met.

Where Sigma Fits In

Planning to Manufacture a New Component?

Retooling for New Parts on Existing Machines?

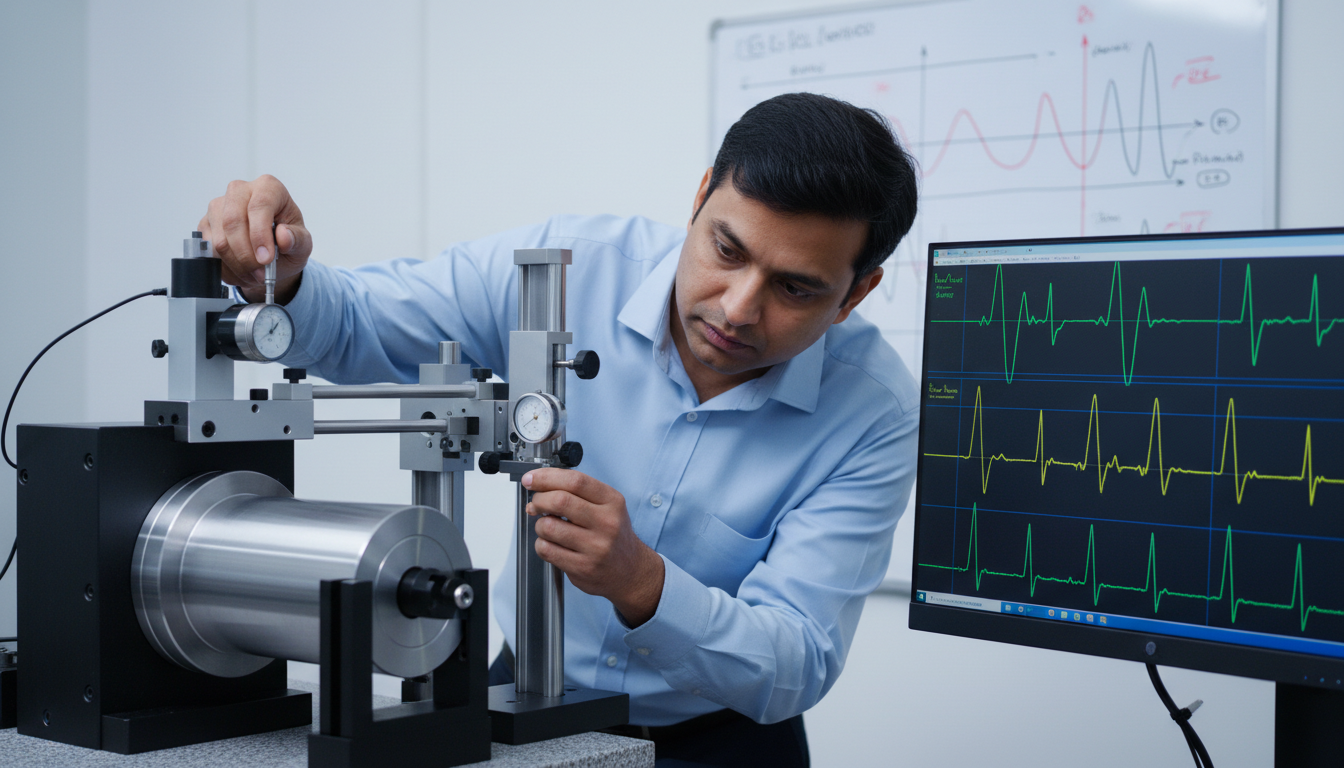

Optimizing Live

Production

The Sigma 7-Step Playbook

Discover & Diagnose

We learn the part and your reality—tolerances, takt, machines, coolant, gauging, and constraints.

Deliverables: machining concept options, feasibility notes, risk register, draft tool/operation list.

Architect the Process

We design for capability and takt—not either/or—and lay out the flow across your assets.

Deliverables: cycle-time study, rough/finish windows, machine split, clamping principles, acceptance criteria.

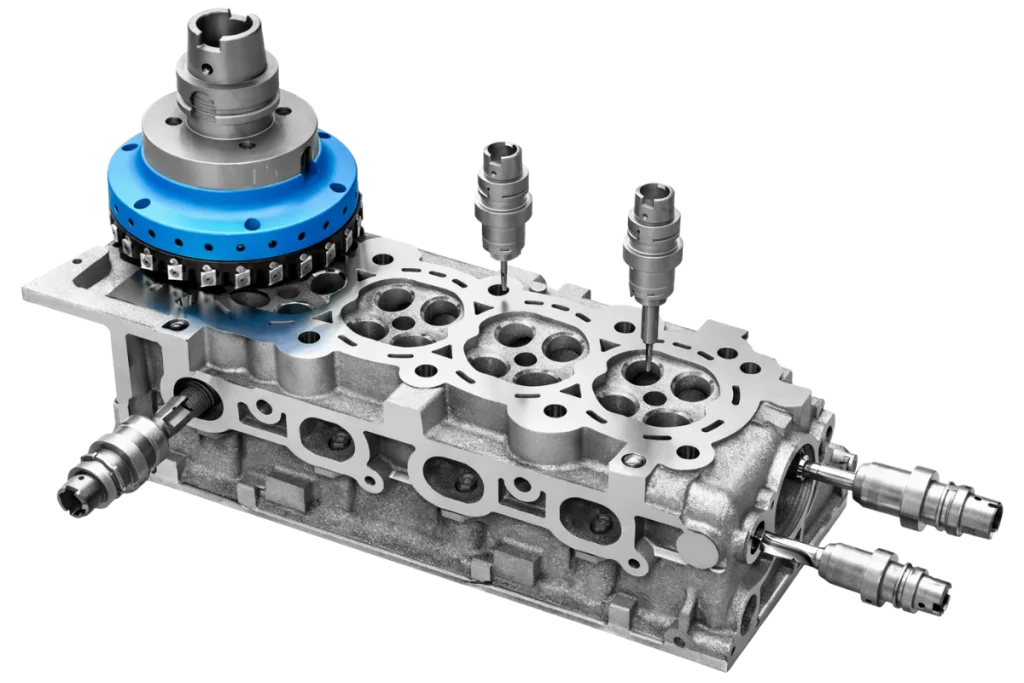

Engineer Tools & Fixtures

One accountable team for cutting tools, combination concepts, and μ-true fixturing.

Deliverables: tool & fixture engineering, drawings, step-reduction concepts, assembly/setting/balancing at Sigma.

Prove It Digitally (Safe-Reach & Collision)

We validate reach, clearances, and stability before chips fly.

Deliverables: 3D collision/clearance study, tool-restriction map, harmonisation of tool–fixture–workpiece–machine envelope.

Program & Parameterise

NC that protects capability—and your cycle time.

Deliverables: OEM-specific NC programs, special cycles (e.g., interpolation turning/trochoidal), customer-specific structure, locked parameter windows.

Launch & Lock Capability

We commission on site (or at Sigma if schedules are tight), then prove capability.

Deliverables: machine geometry check log, full break-in, process capability study, PPAP pack, operator/setter handover.

Sustain & Scale

Keep the line stable—and ready to grow.

Deliverables: start-up floor support, troubleshooting, training, inventory optimisation (VMI/min-max/standardisation), monthly performance huddles, change control for variants.

Want us to get back to you?

Recent Blogs

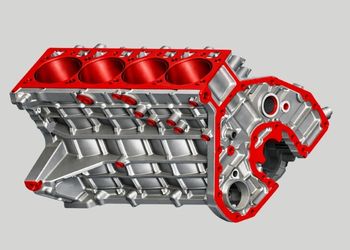

4 Cylinder Block

4 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

3 Cylinder Block

3 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

Tlb Transmission

Tlb Transmission Set-up OP-10 Operation Details : Milling, Drilling, Holemill,