On the Floor Technical Support

Why Sigma

- Shopfloor-first problem solving with fast response

- Specialists who’ve stabilised complex engine/transmission processes

- Parameter tuning within safe windows, not risky experimentation

- Tool-life stabilisation with practical countermeasures

- Improves output without disrupting takt

- Clear issue logs, closures, and repeat-prevention actions

- Operator/setter method discipline built into the fix

- Weekly KPIs that show impact: tool life, scrap, throughput, downtime

Where Sigma Fits In

Launch Phase Needs Extra Engineering Bandwidth?

Live Production Has Frequent Quality/Tooling Firefights?

Stabilise the Line While It Keeps Running

Live Diagnosis & Root Cause

Scope: Drift, chatter, burrs, finish variation, breakages, sudden scrap.

Deliverables: issue log, root-cause notes, containment actions.

Parameter Tuning Within Safe Windows

Scope: Feed/speed/DOC tuning without compromising quality or tool life.

Deliverables: revised parameter windows, do/don’t rules, stability checklist.

Tool Life Improvement Actions

Scope: Insert strategy, edge prep, coolant direction/pressure, wear control.

Deliverables: tool-life uplift plan, breakage countermeasures, baseline vs new.

Setup, Offsets & Method Discipline

Scope: Setting, offsets, touch-off, changeover sequence, mistake-proofing.

Deliverables: setup SOP updates, quick-check steps, training inputs.

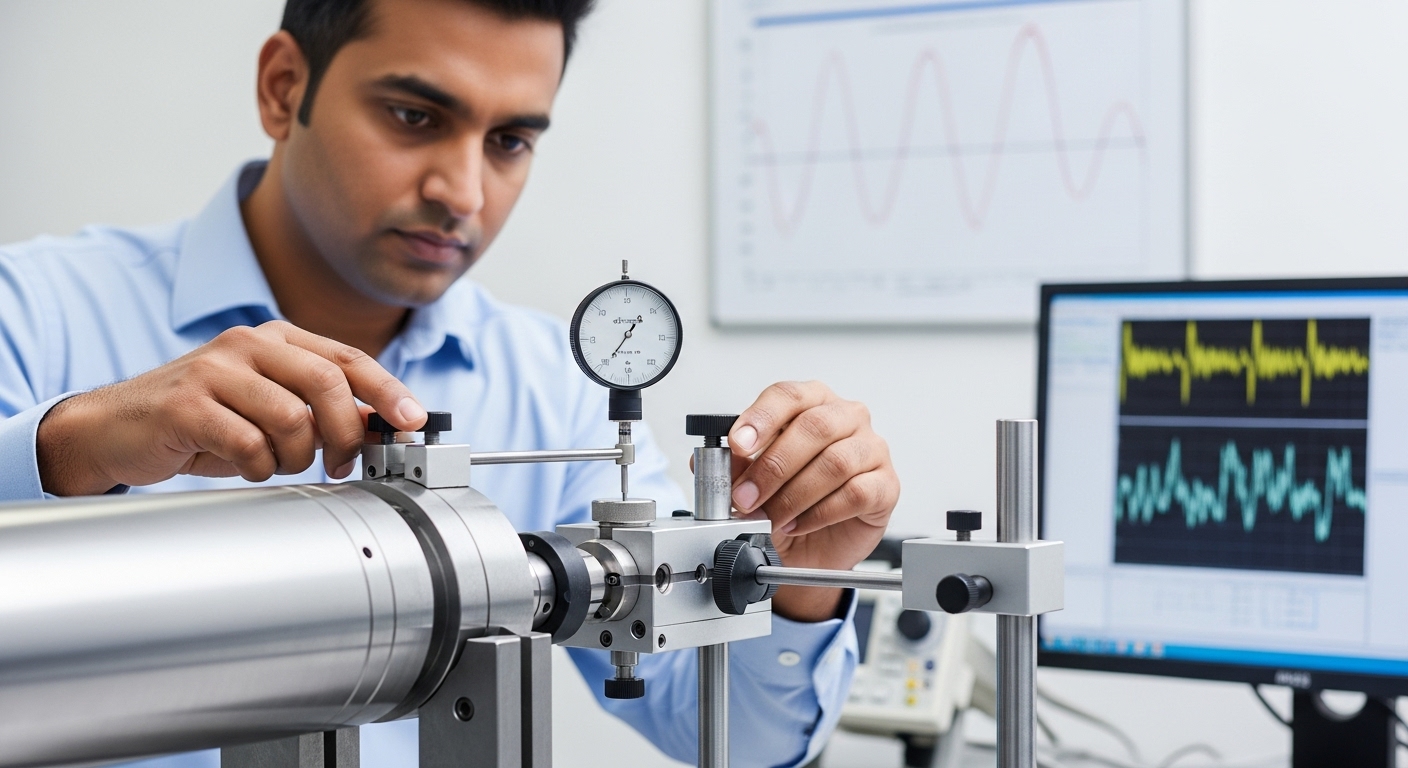

Quality Gate Alignment (Gauging & Checks)

Scope: Critical dimensions, measurement method, sampling logic.

Deliverables: check plan, gauge alignment notes, acceptance criteria reminders.

Weekly Stabilisation KPIs

Scope: Track what matters: tool life, scrap, rework, downtime, throughput.

Deliverables: weekly KPI sheet, actions tracker, sustain plan.

Want us to get back to you?

Recent Blogs

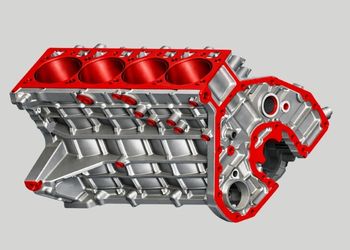

4 Cylinder Block

4 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

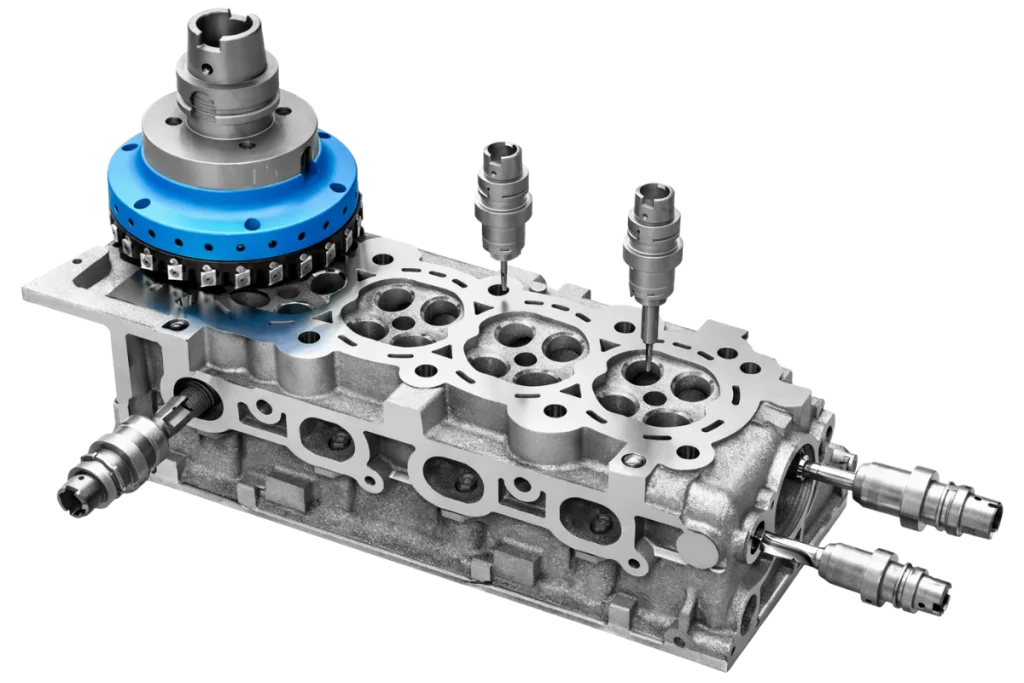

3 Cylinder Block

3 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

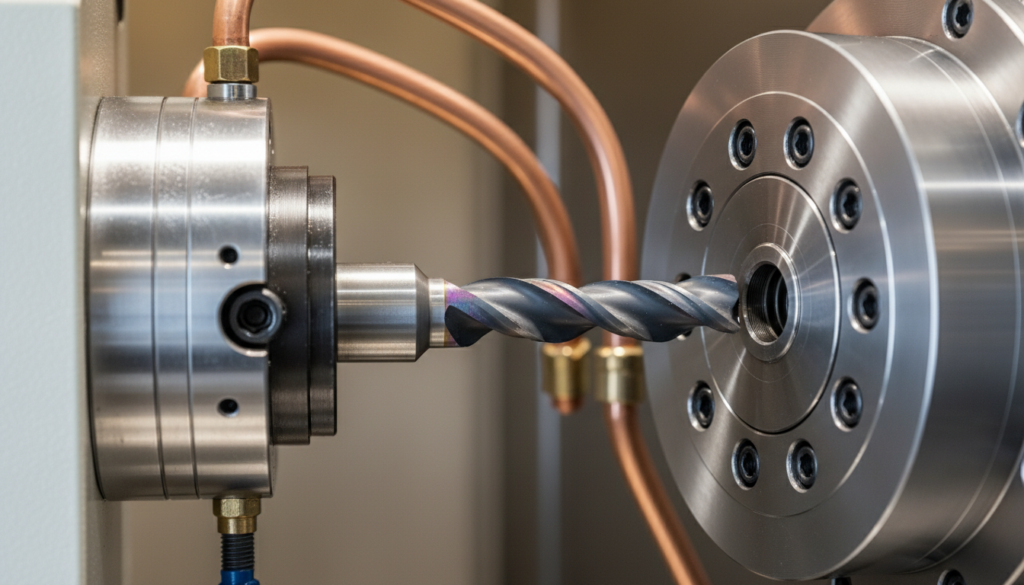

Tlb Transmission

Tlb Transmission Set-up OP-10 Operation Details : Milling, Drilling, Holemill,