CPC Saving Program

Why Sigma

- Savings focused on verified CPC, not theoretical “improvements”

- Baseline-first approach with transparent before/after proof

- Tool life + cycle time balanced to protect quality and throughput

- Step-reduction and modern strategies proven on shop floors

- One team owning trials, documentation, and standardisation

- Root-cause view on abnormal consumption and rework drivers

- KPI cadence your team can actually run weekly

- Sustainment built-in: SOPs, parameter windows, control plan

Where Sigma Fits In

CPC Targets Have Tightened for an Existing Part?

Production is Stable but Costs Are Creeping Up?

Reduce CPC Without Breaking the Process

CPC Baseline & Loss Map

Scope: Cycle time, tool consumption, downtime, scrap/rework, changeovers.

Deliverables: CPC baseline sheet, top loss drivers, Pareto.

Opportunity Identification & Prioritisation

Scope: Tooling, strategy, step reduction, coolant optimisation, standardisation.

Deliverables: savings funnel, impact vs effort matrix, 30/60/90 plan.

Trial Design & Validation Plan

Scope: Controlled trials with quality + takt protected.

Deliverables: trial sheets, measurement plan, risk controls.

Tool Life & Parameter Window Optimisation

Scope: Rough/finish windows, insert strategy, stability tuning.

Deliverables: locked parameter windows, tool-life target uplift, breakage reduction plan.

Step Reduction & Cycle-Time Compression

Scope: Combine operations, reduce tool changes, improve approach paths.

Deliverables: revised op-sequence, updated tool list, cycle-time delta proof.

Standardisation & Sustainment

Scope: SOP updates, training, audit checks, governance cadence.

Deliverables: updated work instructions, training notes, monthly KPI tracker.

Want us to get back to you?

Recent Blogs

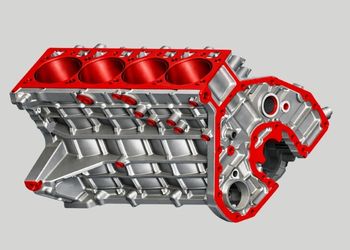

4 Cylinder Block

4 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

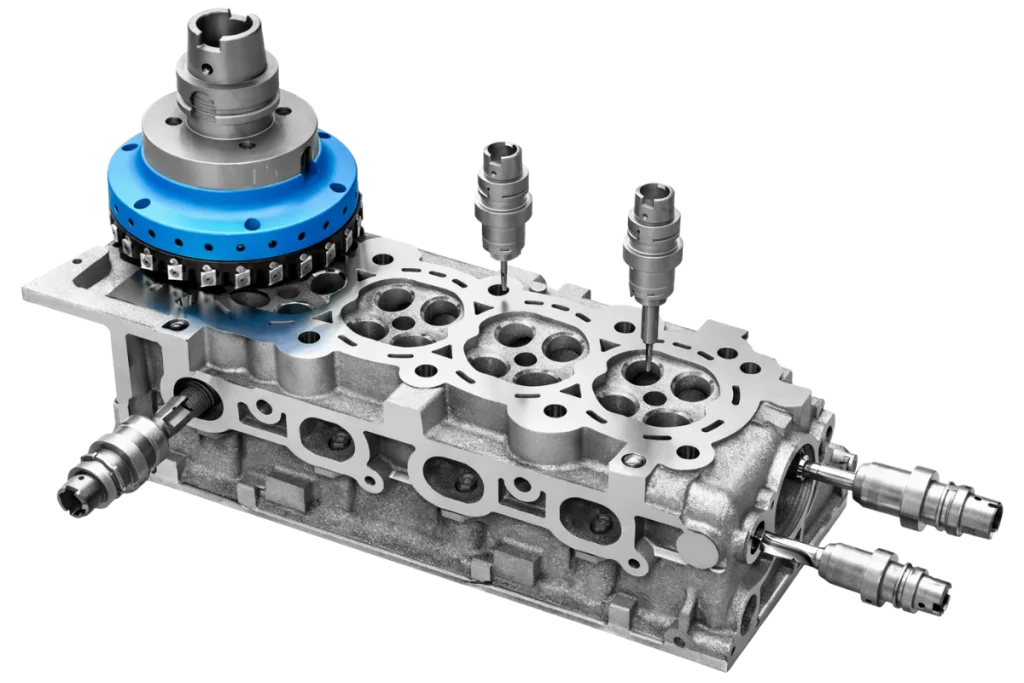

3 Cylinder Block

3 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

Tlb Transmission

Tlb Transmission Set-up OP-10 Operation Details : Milling, Drilling, Holemill,