Aerospace Components Tooling

Comprehensive range of tooling’s for aerospace equipment

Aircraft components are made of high tensile, tough materials like High-Density Special Steel, Titanium and Composites. Sigma Tooling’s offers unique tooling for 5 majors components.

We provide complete set of tooling for following components.

• Rear Cone

• Titanium Center Piece

• Bearing Housing

• Engine Cases

• Manifolds

Product Range

Tangential Boring Bars

- Allows very high feed rates against ISO inserts.

- Extremely stable cutting.

- High feed inserts.

- More cutting edges possible.

- Tough cutting edge & high positive geometry.

- Ex-stock availability for all grades.

Finish Boring Bars

- Sigma offers wide range of standard and combination of Finish Boring Bars. Finish Boring Bars are suitable for machining close tolerance bores.

- Our Finish Boring Bar range starts from Diameter 24 to 1030 mm and they are dynamically balanced at G2.5 and 10,000 RPM.

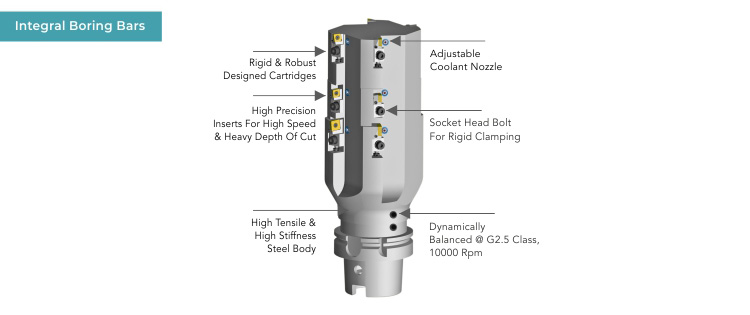

Integral Boring Bars

- Integral boring bars are offered with different integral tapers like BT, ISO/SK (DIN69871), HSK, NT etc. These are suitable for high loads and maintain rigidity throughout machining operation.

- Integral boring bars do not have runout problems and provides highest torque transmission to the operation. These tools are balanced at higher rpm.

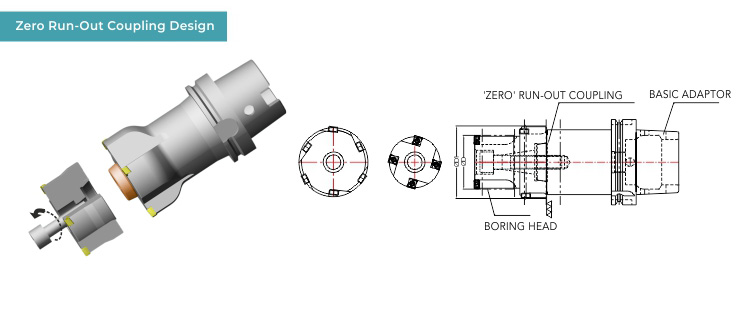

Zero Run-Out Coupling Design

Zero Run-Out Coupling

Sigma has designed the zero run-out coupling to maintain axial & radial run-out within close tolerance of ±0.005mm. It is rigid because of face butt clamping.

High Positive Tangential-Insert

Sigma tangential cutting insert with tough cutting edge & high positive chip breaker reduce cutting forces.

Boring Head

Boring head is made of special tool steel which is having high tensile strength & high stiffness with unique surface treatment which gives smooth surface, excellent chip flow & increased body life by 30~35 % as compare with regular tool steel.

Technical Data For Boring Bar

Coolant Hole

Sigma has designed a special adjustable coolant system which can be set very easily on insert cutting points and being special nozzle system it gives high pressure to the flow of coolant which helps fast cutting and easy flow of chips.

Cartridge

Sigma customized cartridges are compact and robust in design and also they sustain heavy cutting forces.

Balancing

Balancing of rotary tools plays a very important role in its performance. Boring bars at sigma are dynamically balanced as per the service RPM. It also helps in increasing the life of machine spindle and accuracy of the bore.

Class of Taper

Holding system requires high precision with fine grinding. We at sigma maintain CLASS of TAPER as per ISO Class AT2.

Coating

Coating of customized boring bars is an important aspect. We have a unique coating setup which prevents the wear and tear of the tools and also increases its life by 35%.