About Us

Our Story

Sigma Toolings began with a belief that still guides us today.

If you can control the process, you can control the outcome.

Not just on the first part. On every part. Every shift.

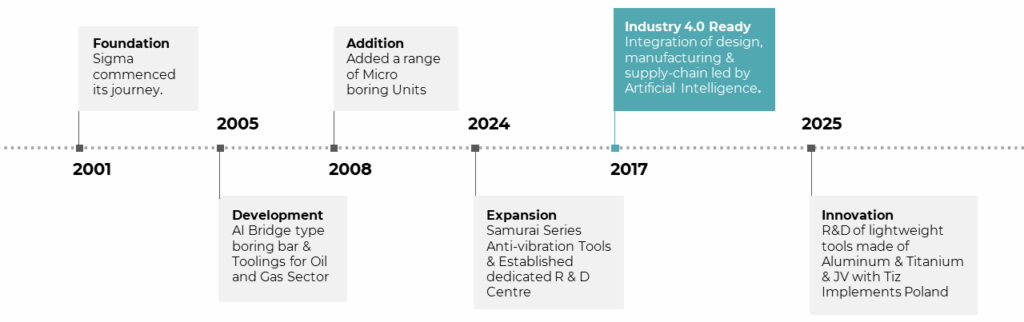

Sigma Toolings’ story starts in 2001, built around a simple shopfloor truth: in machining, output doesn’t improve with “better tools” alone, it improves when tooling is engineered around the process outcome (cycle time, geometry, finish, repeatability).

Over the years, Sigma grew into a specialist in customised, high-end tooling solutions, applying deep application know-how across core mechanical industries and backing it with a portfolio that spans boring, drilling, grooving, chamfering, toolholders and more, along with a capability to support everything from Comprehensive Tooling Solutions for Projects to Tool Crib Management for customers who want reliability at scale.

What stands out in Sigma’s journey is the deliberate shift from “supplying tools” to building capability with a strong focus on R&D and innovation, and an emphasis on digital and productivity-led programs focusing on project management with productivity improvement mindset. That philosophy shows up in how Sigma positions its tooling families and specialties designed to help customers push cutting parameters while protecting tolerance and finish.

Now, Sigma’s is clearly global and future-facing. Our Made-in-India toolings being exported to 28+ countries, and a new state-of-the-art Smart Factory is being designed for global expectations from day one. Sigma is built to faster turnaround, stronger quality systems, traceability, deeper in-house capability, and a dedicated R&D facility to solve tougher problems.