3 Cylinder Block

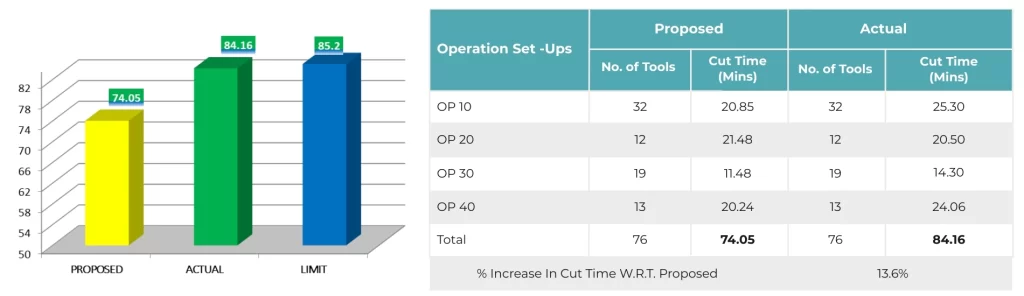

Set-up OP-10

Operation Details : Milling, Drilling, Tapping And Reaming

Cut Time : 25.3 Min

No of Tools : 32 Nos

Set-up OP-20

Operation Details : Crank Boring, Liner Bore, Web Milling

Cut Time : 20.5 Min

No of Tools : 12 Nos

Set-up OP-30

Operation Details : Face Milling, Drilling, Reaming, Burnish

Cut Time : 14.3 Min

No of Tools : 19 Nos

Set-up OP-40

Operation Details : Cam Bore, Thrust Milling, Bore Finish

Cut Time : 24.06 Min

No of Tools : 13 Nos

Sigma’s tooling solution for 3-cylinder blocks focused on achieving high precision across complex features such as bores, seats, and critical mating surfaces. By leveraging advanced boring bars, grooving tools, and anti-vibration technology, we ensured stable machining conditions even for small, intricate parts. Our solution enhanced tool life, reduced cycle time, and delivered consistent results, making sure that each component met stringent quality standards while keeping production cost-efficient.

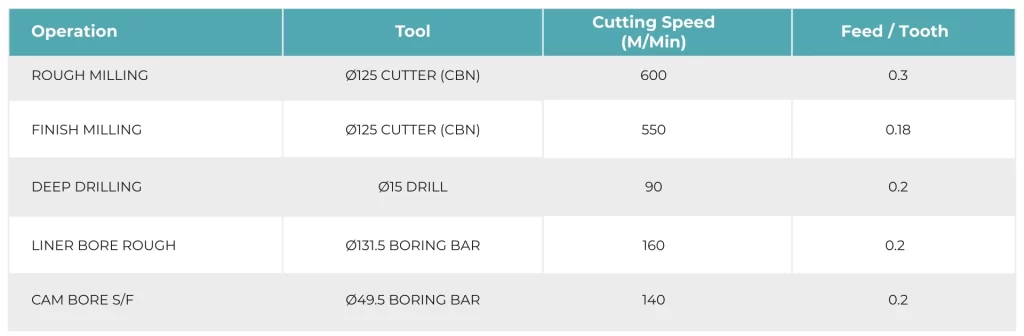

Cutting Tools - Model

Cutting Parameters

Summary