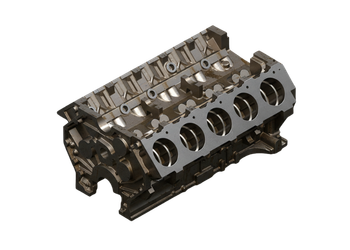

Dv 10 Cylinder Block

Set-up OP-10

Operation Details : Milling, Drilling, Threadmilling

Cut Time : 22.61 Min

No of Tools : 33 Nos

Set-up OP-20

Operation Details : Gundrill, Shellmill, Crank , Notch And Web Milling

Cut Time : 81.17 Min

No of Tools : 25 Nos

Set-up OP-30

Operation Details : Face Milling, Drilling, Reaming, Burnish

Cut Time : 86.96 Min

No of Tools : 36 Nos

Set-up OP-40

Operation Details : All Cam Bore, Thrust Milling, Bore Finish

Cut Time : 208.35 Min

No of Tools : 28 Nos

For the DV-10 cylinder block production, Sigma delivered a tailored tooling solution that ensured accurate machining of bores, faces, and threads. By utilising high-performance boring bars, precision drills, and vibration-dampening tools, we improved tool life, machining accuracy, and cycle times. The result was a production process that maximised efficiency while maintaining the necessary quality control to meet the demanding specifications of the DV-10 block.

Cutting Tools - Model

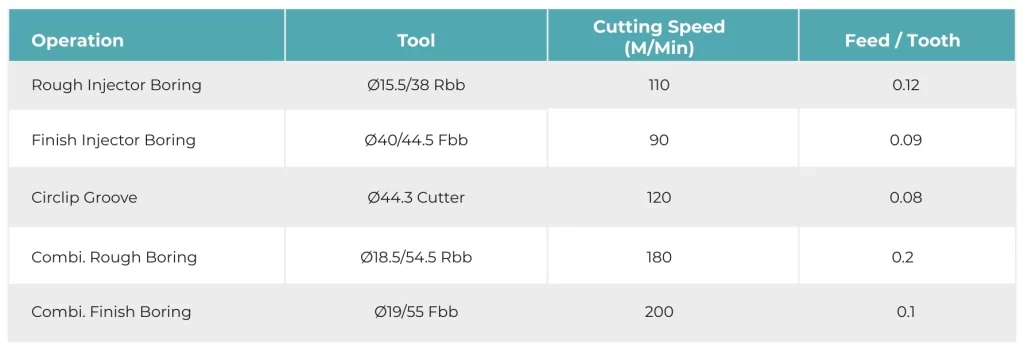

Cutting Parameters

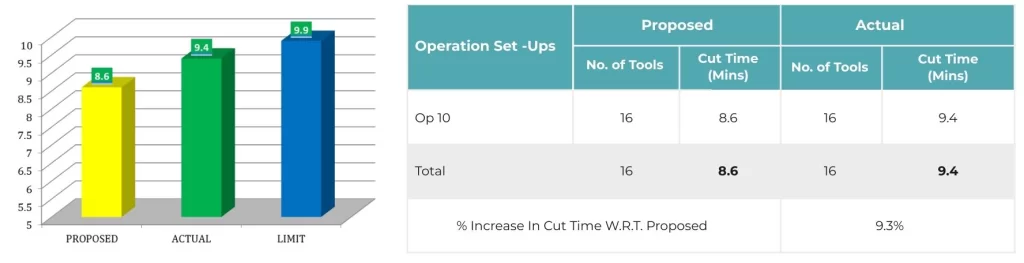

Summary

Within 15% Tolerance