Retooling and Maintenance

Why Sigma

- Retooling engineered for capability + takt, not “make it run”

- Strong fitment study: machine envelope, rigidity, coolant, gauging

- Tool + fixture upgrades that remove drift, chatter, and burr issues

- Maintenance discipline that prevents repeat breakdowns

- Fast ramp support with on-floor stabilisation

- Acceptance criteria and buyoff packs that teams can rely on

- Spares and PM planning tied to criticality and uptime

- Proven approach on retooling for engine/transmission families

Where Sigma Fits In

Need New Parts on Machines You Already Own?

Recurring Issues from Worn Fixtures/Tools?

Relaunch Stable Output on Existing Assets

Fitment Study (Machine vs Part Reality)

Scope: Capability gap, reach/clearance, rigidity, coolant and gauging alignment.

Deliverables: fitment report, feasibility notes, risk register.

Process Refresh & Workflow Re-shape

Scope: Operation sequence, machine split, takt alignment, setup strategy.

Deliverables: revised process plan, cycle-time study, acceptance criteria.

Tooling Upgrade / Re-engineering

Scope: New tools, combination concepts, step reduction, chip control.

Deliverables: updated tool list, tool specs, parameter windows.

Fixture Reconditioning & Robustness Upgrades

Scope: Restore datums, clamps, locators; improve repeatability and ergonomics.

Deliverables: fixture restoration buyoff, drawings/updates, clamping principles.

Preventive Maintenance & Spares Planning

Scope: PM frequency, inspection points, min-max spares, regrind loop.

Deliverables: PM checklist, spare list, tool/fixture health log format.

Re-validation & Ramp Support

Scope: Break-in, capability proving, stabilisation actions on floor.

Deliverables: capability study, handover notes, ramp stabilisation plan.

Want us to get back to you?

Recent Blogs

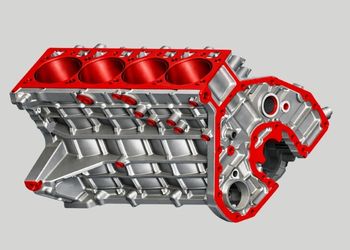

4 Cylinder Block

4 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

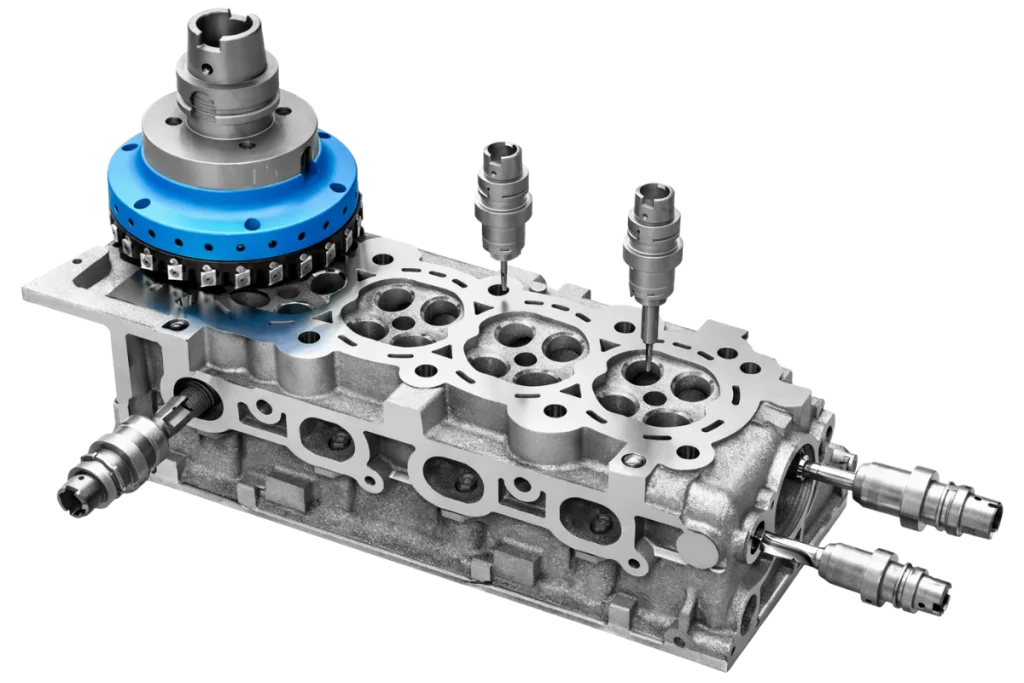

3 Cylinder Block

3 Cylinder Block Set-up OP-10 Operation Details : Milling, Drilling,

Tlb Transmission

Tlb Transmission Set-up OP-10 Operation Details : Milling, Drilling, Holemill,