4 Cylinder Block

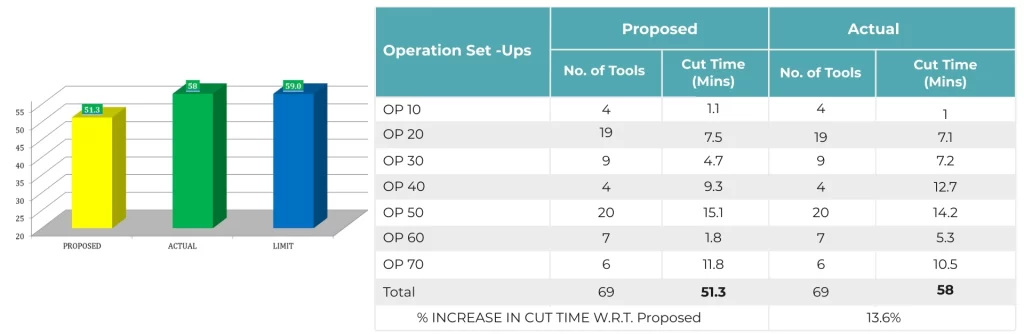

Set-up OP-10

Operation Details : Milling, Drilling, Reaming

Cut Time : 1.0 Min

No of Tools : 4 Nos

Set-up OP-20

Operation Details : Milling, Gundrill, Tapping

Cut Time : 7.1 Min

No of Tools : 19 Nos

Set-up OP-30

Operation Details : Drilling, Core Drill, Chamfer

Cut Time : 7.2 Min

No of Tools : 9 Nos

Set-up OP-40

Operation Details : Rough & Finish Bore, Side & Face Mill

Cut Time : 12.7 Min

No of Tools : 4 Nos

Set-up OP-50

Operation Details : Rough & Finish Bore, Side & Face Mill

Cut Time : 14.2 Min

No of Tools : 20 Nos

Set-up OP-60

Operation Details : Milling, Drilling, Reaming

Cut Time : 5.3 Min

No of Tools : 7 Nos

Set-up OP-70

Operation Details : Rough & Finish Bore, Grooving

Cut Time : 10.5 Min

No of Tools : 6 Nos

Sigma successfully delivered a comprehensive tooling solution for 4-cylinder block production, ensuring precision machining of critical features such as main bores, valve seats, and cylinder bores. With the use of anti-vibration tooling, precision boring tools, and customised cutting strategies, we optimised cycle times, reduced tool wear, and maintained consistent quality across multiple setups, enabling cost-effective production without compromising performance. Our solution addressed the challenges of high-volume manufacturing while ensuring reliability and repeatability at every stage.

Cutting Tools - Model

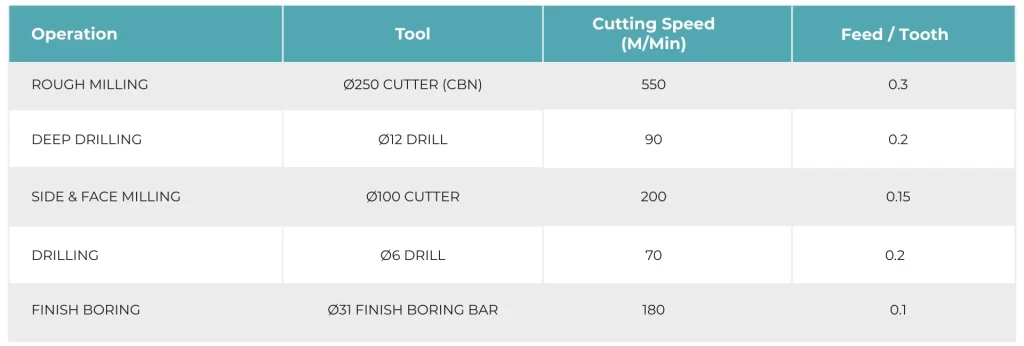

Cutting Parameters

Summary